Galvanic Corrosion and Protection

Metal that is exposed to water is often protected by Sacrificial Anodes to protect it from Galvanic corrosion. We offer the means to measure or monitor the progress of corrosion to ensure action can be taken to prevent or minimise the damage caused.

The three most common questions we receive are related to the broad subject categories below. If you wish to see a complete list of technical articles broadly related to Corrosion and REDOX measurements take a look at our Corrosion Support area. If you cant find what you need please contact us on info@edt.co.uk and we will be happy to offer further advice.

Hull Potential & Boats

Click on the picture to learn more about testing your boats Hull potential or visit our Corrosion Support area.

We stock all of our Corrosion testing products for next day delivery.

Disbondement Testing

Click on the picture to learn more about Cathodic Disbondment or visit our Corrosion Support area.

We stock all of our Disbondment testing products for rapid delivery.

Redox

Click on the picture to learn more about REDOX testing or visit our Technical Support area.

We stock all of our REDOX testing products for rapid delivery.

Galvanic Corrosion in Boats & Other Metal Stuctures

Arming yourself with a simple Boat Meter Kit will enable you to monitor your Hull and other immersed metal components to ensure they are being protected by your anodes. You can also monitor for stray direct current or simply measure how corrosive the water in your mooring is.

Hull Potential

Narrow boats, Aluminium hulls and Titanium racing boats all use Sacrificial anodes. We help you to monitor their effectiveness.

Metal Corrosion in Boats

It is important to understand why corrosion occurs and what steps you may take to prevent it from damaging your assets.

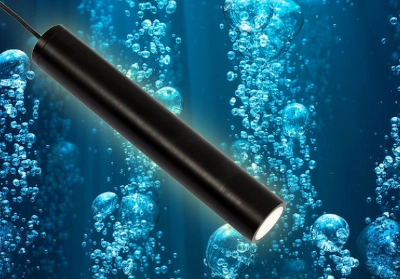

Measuring Hull Potential

A simple test using a Cathodic Protection reference electrode allows you to monitor your Hull and your anodes.

Silver Spoon Myth

Never use a silver spoon as a Reference electrode to measure your Hull potential. We tell you why.

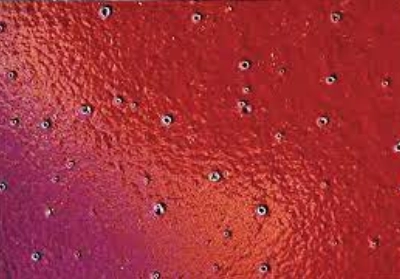

Cathodic Disbondment Testing Explained

When a coating is damaged the exposed metal begins to corrode. This is Disbondment and there is a very simple test for it using a basic meter and a Calomel reference electrode.

Corrosion Questions?

Take a look at our Corrosion support area. If you cant find what you want email us at info@edt.co.uk

Cathodic Disbondment Testing

The disbondment test is very simple. We show a basic set up and what you should look for in the test

Cathodic Over Protection Risks

Protecting your boat or metal structure is very necessary. It is possible however to cause damage by overprotection.